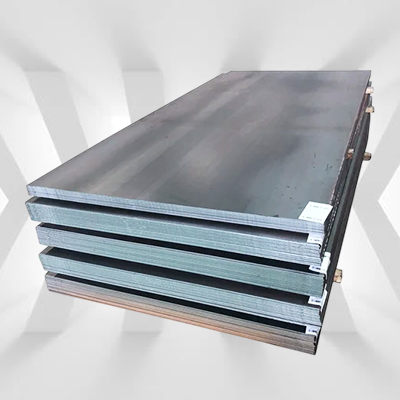

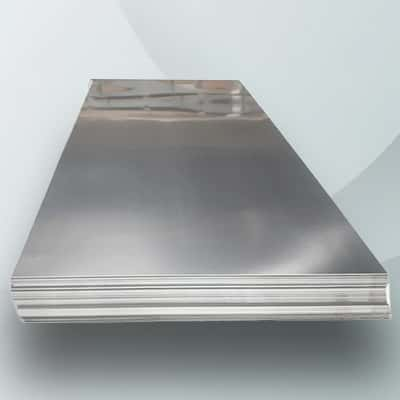

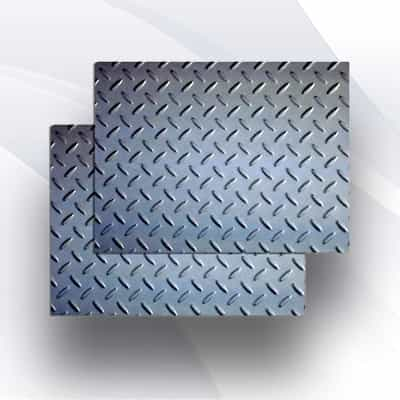

Introduction to MS Hot Rolled Plates

MS Hot Rolled Plates are one of the most fundamental products in the steel industry, widely utilized for their strength, durability, and workability. Manufactured through the hot rolling process at high temperatures, these plates are known for their excellent structural properties and surface finish. They are commonly used in infrastructure development, heavy machinery, shipbuilding, industrial fabrication, automotive frames, bridges, and various other steel structures. Their ability to withstand heavy loads, mechanical stress, and environmental exposure makes them a preferred choice for both indoor and outdoor applications. MS Hot Rolled Plates offer ease of cutting, welding, and forming, allowing engineers and fabricators to mold them as per project needs. The edges of these plates are generally mill-finished, making them suitable for load-bearing operations without the need for further machining. Their uniform thickness and flat surface enable consistent performance in diverse environments, while their affordability makes them a practical material for both large-scale and small-scale projects. Available in various thicknesses, widths, and lengths, MS Hot Rolled Plates are tailored to meet standard industrial requirements. For structural steel applications that demand strength, flexibility, and resilience, MS Hot Rolled Plates are a reliable and effective solution.