Chequered Sheets

Have any Questions? Call us Today!

+91-8510817677Get Best Deal

We are a manufacturer and exporter of Power Conditioning Solutions providing the best quality products and services to our customers.

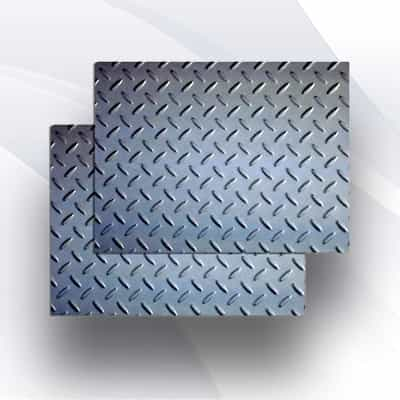

Chequered Sheets

When strength, safety, and style are critical, chequered sheets are the perfect choice for a wide range of applications. Whether it’s in industrial flooring, vehicle manufacturing, or architectural enhancements, chequered sheets deliver unmatched durability and an attractive finish. Manufactured from high-quality steel, aluminum, or other metals, chequered sheets are designed to withstand heavy usage while providing essential slip resistance. Their patterned surface is not only functional but also adds a visual appeal to any installation, making chequered sheets a favorite across industries.

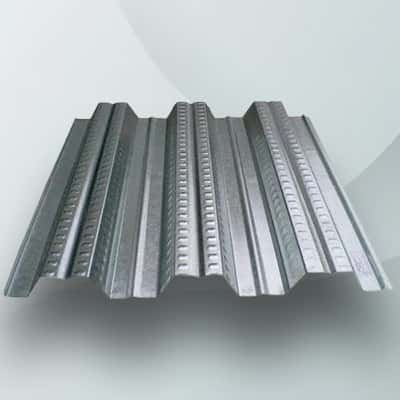

What are Chequered Sheets?

Chequered sheets, also known as diamond plates or tread plates, are metal sheets embossed with a regular pattern of raised lines or diamonds. They are primarily used for flooring and surface protection purposes because of their anti-slip properties. Chequered sheets can be manufactured from materials like mild steel, stainless steel, and aluminum, depending on the intended use and required strength.

Key Benefits of Chequered Sheets

1. Slip Resistance

The raised patterns on chequered sheets provide excellent grip, preventing slips and falls even in wet or oily conditions.

2. High Durability

Chequered sheets are made from strong materials that resist wear, corrosion, and impact, making them ideal for heavy-duty applications.

3. Easy Maintenance

Chequered sheets are easy to clean and maintain, ensuring they retain their aesthetic appeal and functionality for years.

4. Aesthetic Enhancement

Chequered sheets add a sleek, industrial look to floors, walls, and structures, making them popular in architectural projects.

5. Lightweight Options Available

Aluminum chequered sheets provide high strength without adding excessive weight, which is crucial for transportation and automotive industries.

Applications of Chequered Sheets

Chequered sheets are extremely versatile and used across multiple sectors:

- Industrial Flooring – Warehouses, factories, workshops, and plants require durable, non-slip surfaces.

- Vehicle Footplates – Trucks, buses, trailers, and fire trucks use chequered sheets for safety and durability.

- Architectural Interiors – Modern interiors feature chequered patterns for a rugged, stylish appeal.

- Ramps and Staircases – Public and private ramps benefit from the anti-slip features of chequered sheets.

- Shipbuilding and Marine – Harsh marine conditions are ideal for corrosion-resistant chequered sheets.

- Toolboxes and Cabinets – Strong, lightweight covers and panels use chequered sheets.

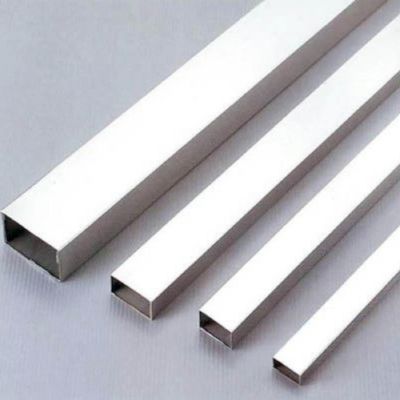

Types of Chequered Sheets

1. Mild Steel Chequered Sheets

MS chequered sheets are known for their strength and affordability, widely used in heavy-load environments.

2. Stainless Steel Chequered Sheets

SS chequered sheets offer excellent corrosion resistance and are perfect for sanitary and marine applications.

3. Aluminum Chequered Sheets

Aluminum chequered sheets are lightweight, corrosion-resistant, and used where weight-saving is crucial, like in vehicles and aircraft.

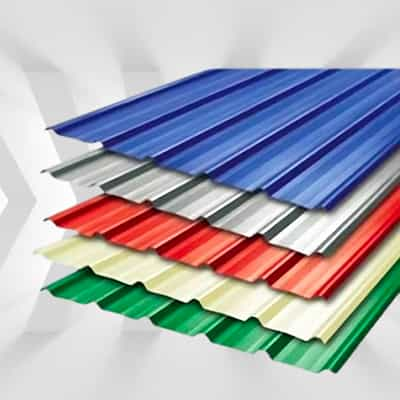

4. Galvanized Chequered Sheets

Galvanized chequered sheets feature a protective zinc coating that enhances their corrosion resistance for outdoor use.

Features of High-Quality Chequered Sheets

- Consistent Pattern: Uniform embossing for maximum slip resistance.

- Perfect Thickness: Available in various thicknesses to suit light to heavy-duty requirements.

- Superior Finish: Smooth edges and clean patterns for enhanced appearance and safety.

- Durable Coatings: Options like powder coating and galvanization extend lifespan.

- Custom Sizes: Sheets can be customized to specific dimensions based on project needs.

Manufacturing Process of Chequered Sheets

The production of chequered sheets involves rolling metal under high pressure through patterned rollers that imprint the raised texture. Hot rolling and cold rolling are two common methods. Post rolling, sheets may be cut, polished, or coated depending on the end-use requirements.

Choosing the Right Chequered Sheet

Selection depends on various factors such as:

- Material: Steel for heavy-duty, aluminum for lightweight applications.

- Thickness: Thicker sheets for heavy loads; thinner for decorative uses.

- Pattern: Diamond, teardrop, or custom designs based on slip-resistance needs.

- Coating: Galvanized or powder-coated for increased life in harsh environments.

Maintenance Tips for Chequered Sheets

- Regular Cleaning: Prevents dirt and moisture buildup, maintaining slip resistance.

- Surface Inspection: Check for scratches or dents that may reduce grip.

- Protective Coatings: Reapply coatings if signs of wear or rust appear.

- Polishing: Stainless steel sheets can be polished to retain their shine and appearance.

Why Choose Our Chequered Sheets?

Our chequered sheets offer unmatched quality and performance:

- Made with premium-grade materials ensuring strength and durability.

- Advanced manufacturing techniques for perfect patterns and smooth surfaces.

- Custom size and thickness availability to meet project-specific requirements.

- Excellent corrosion resistance with optional galvanization or powder coating.

- Timely delivery and competitive prices with a customer-first approach.

Frequently Asked Questions (FAQs)

1. Are chequered sheets suitable for outdoor use?

Yes, especially galvanized and stainless steel chequered sheets are highly resistant to outdoor conditions.

2. What is the standard thickness of chequered sheets?

Thickness can vary from 2mm to 12mm depending on the application requirements.

3. Can chequered sheets be painted?

Yes, they can be powder-coated or painted for aesthetic and protective purposes.

4. How do I select between aluminum and steel chequered sheets?

Choose aluminum when lightweight and corrosion resistance are priorities; steel when strength and cost-effectiveness are needed.

5. Can you supply customized chequered sheets?

Absolutely, we offer custom sizes, thicknesses, and even pattern designs as per your project requirements.

Conclusion: Strengthen and Beautify with Chequered Sheets

Chequered sheets are an essential solution for creating safe, durable, and visually appealing spaces. Whether it's for heavy industrial use or aesthetic architectural projects, chequered sheets provide the perfect combination of functionality and design. Invest in our premium range of chequered sheets and experience the difference in quality, performance, and satisfaction!

Contact us today for expert advice and the best deals on high-quality chequered sheets tailored to your needs!