Deck Sheet Dealers Delhi NCR | Shree Laxmi Steels

Deck Sheet Dealers Delhi NCR | Shree Laxmi Steels

Introduction

Deck sheets are indispensable in modern construction—offering structural support, aesthetic appeal, and long-lasting performance. Whether you're working on residential, commercial, or industrial projects in Delhi NCR, choosing the right deck sheet dealer can simplify procurement, streamline installation, and ensure compliance with quality standards. This guide covers everything you need to know—from materials and profiles to pricing, delivery, and dealer selection.

1. What Are Deck Sheets and Why They Matter

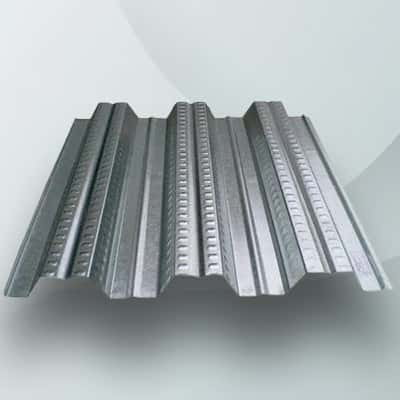

Deck sheets, also known as decking sheets or roof decks, are corrugated metal panels (usually steel or aluminum) used as load-bearing floors or roofs in composite construction.

- Structural support: Deck sheets act as a permanent formwork, supporting fresh concrete and resisting loads until the composite slab cures.

- Durability: High-quality sheets resist moisture, corrosion, and environmental stress—ensuring a long service life.

- Installation efficiency: Deck sheets are quickly laid and fixed, reducing labor time and scaffolding, which ultimately lowers project costs.

- Aesthetic enhancements: Some profiles offer attractive patterns suited for exposed ceilings or soffits.

- Versatility: Ideal for slab-on-deck, mezzanine construction, roofs, and industrial flooring.

Selecting top-grade deck sheets and reliable dealers guarantees installation quality, project timelines, and long-term structural integrity.

2. Materials Used in Deck Sheets

- Galvanized Steel

- Coated with zinc to resist rust; standard for most structural needs.

- Thickness ranges from 0.7â¯mm to 1.5â¯mm (24–18â¯gauge), depending on load and span.

- Galvalume (Aluzinc) Steel

- Steel coated with 55% aluminum and 45% zinc offering enhanced corrosion resistance.

- Ideal for coastal or high-moisture applications.

- Color-Coated Steel

- Pre-painted sheet provides both protection and aesthetic appeal—used for exposed roofs and ceilings.

- Aluminum Sheets

- Lightweight and corrosion-resistant but more expensive; used in specialized applications.

- Fire-Resistant & Insulated Decking

- Includes coatings or composite decks with EPS or PIR cores for insulation and fire resistance.

Understanding material properties helps you choose sheets that match structural and environmental demands.

3. Standard Profiles & Specifications

- Trapezoidal (Tuff-Rib): Known for structural rigidity and reduced steel thickness requirements.

- Floor Deck (Medium/High Span): Designed to support concrete; typically 80–150â¯mm rib height.

- Roof Sheet (Maxi/Rib): Thinner ribs ideal for roof slope; aesthetic ceiling lines.

- Soffit Decking: Exposed internals; smooth profiles ideal for gallery ceilings.

Key specs to verify:

- Sheet width – Effective width (cover width) vs. total width

- Cover length – Standard up to 12â¯m (longer lengths by custom order)

- Rib height & pitch – Affects span and load capacity

- Steel grade – IS 513 SPGL, S350 GD, or equivalent

- Coating class – Z275 for galvanized, AZ150 for Galvalume, or pre-painted paint spec

Always ask for datasheets, structural performance charts, and load-span tables from your dealer.

4. Advantages of Buying in Delhi NCR

- Wide dealer network – Dealers source sheets from local mills like JSW, Tata Steel, JSPL, and Essar.

- Fast logistics – Reduced transit time and minimized freight compared to distant regions.

- Sample verification – Inspect physical samples onsite instead of relying on photos.

- Competitive pricing – Volume-driven pricing and frequent dealer promotions.

- After-sales support – Local teams can assist with handling, installation advice, and problem resolution.

When serving large-scale projects across Delhi, Noida, Gurugram, Ghaziabad, and Faridabad, convenience and reliability matter most.

5. Choosing the Right Deck Sheet Dealer

Consider the following when selecting a dealer:

- Product Range – Do they stock all necessary profiles (floor, roof, soffit)?

- Inventory Size – Stock ready-to-deliver for urgent requirements?

- Technical Expertise – Can the dealer supply load-span charts, structural guidance, or layout suggestions?

- Quality Assurance – Certification from mills, sample testing, and mill test certificates (MTCs).

- Customization Capabilities – Cutting to length, nesting details, bundling, and handling options.

- Pricing Transparency – Clear breakdown: sheet material, coating, cutting, transport, taxes.

- Delivery & Handling – Crane unloading, bundling methods, rust preventing, edge protection.

- Installation Support – Guidance on fasteners, sealants, underlayment, and lap details.

- After-Sales Service – Inspection visits, solving installation issues, offering replacements.

- Reviews & References – Feedback from past clients—contractors, architects or developers.

6. Pricing & Cost Considerations

Deck sheet prices depend on factors such as:

- Base steel cost – Market fluctuations impact raw material prices.

- Coating material – Galvalume and color coated sheets cost more than plain galvanized.

- Steel thickness and grade – Thicker and higher-grade sheets incur higher cost.

- Profile complexity – Deep or complex profiles may cost slightly more.

- Cutting, handling, and transport – Dealer handling and distance to site matter.

| Material / Profile | Thickness | Rate (â¹ per sqâ¯m) |

|---|---|---|

| Galvanized Floor Deck | 0.8â¯mm | â¹300 – â¹350 |

| Galvalume Floor Deck | 0.8â¯mm | â¹350 – â¹400 |

| Color-Coated Roof Sheet | 0.7â¯mm | â¹320 – â¹380 |

| Roof Deck Plain Galvanized | 0.7â¯mm | â¹280 – â¹330 |

| High-Span Floor Deck | 1.0â¯mm | â¹400 – â¹450 |

7. How to Place an Order

- Confirm requirement – area, length, thickness, profile, coating.

- Collect samples – physical ones for approval.

- Request formal quotations – itemized, including all services.

- Agree on delivery schedule – critical for concrete casting deadlines.

- Finalize payment & logistics – advance vs. credit, truck/unloading.

- Take delivery – inspect for damage, coating issues, dimensional accuracy.

- Document receipt – sign off bundles and quality status with timestamp.

8. Installation Tips

Even high-quality deck sheets fail if incorrectly installed:

- Use proper fasteners and torque settings.

- Stagger sheet ends every 2–3 sheets to minimize leaks.

- Seal joints with recommended tape or sealant.

- Use protective mats for scaffold or plank movement.

- Clean and prime cut edges immediately to prevent rust.

A reliable dealer should offer technical sheets, accessory recommendations, and installation guides.

9. Sustainability & Durability Factors

Talk to your dealer about:

- Life-cycle costing – durable coatings reduce maintenance and replacement costs.

- Recyclability – steel substrates are 100% recyclable at end-of-life.

- Energy efficiency – reflective color-coated sheets can reduce HVAC loads.

- Fire safety – steel decks are non-combustible; compliant with IS 15961 standards.

10. Choosing Shree Laxmi Steels

For reliable deck sheet supply in Delhi NCR, Shree Laxmi Steels stocks a wide range of galvanized, galvalume, and color-coated deck profiles, supports custom lengths and technical guidance, offers competitive local pricing, and ensures fast delivery and expert installation support.

FAQs About Deck Sheet Dealers in Delhi NCR

1. What profile and thickness should I choose for floor deck spans?

For spans up to 3.5â¯m under live loads, a 0.8â¯mm thick floor deck with rib height 80–100â¯mm is ideal. Higher spans (up to 5â¯m) may require 1.0â¯mm thick or high-span profiles. Always refer to supplier’s span-load charts.

2. How does Galvalume compare to galvanized steel for durability?

Galvalume offers superior corrosion resistance with a 55% aluminum–45% zinc coating, compared to pure zinc Galvanized. It’s especially beneficial for coastal or humid regions, lasting 20–30% longer.

3. Can I expose deck sheets architecturally instead of concealing?

Yes—color-coated profiles or soffit-deck types are designed for exposed ceilings, offering aesthetic finishes. Ensure even coating and high-SRI (solar reflectance index) for thermal comfort.

4. Do deck sheets require maintenance after installation?

Minimal maintenance is sufficient – keep surfaces clear of debris, ensure edge finishing is intact, and immediately repair any scratches or cut-edge corrosion with compatible primer.

5. How do I calculate the quantity needed for a project?

Measure area in sqâ¯m and divide by sheet coverage width (e.g., 600â¯mm). Round up 5–10% for overlaps and wastage. Also, calculate additional length for lap and nesting.

Final Thoughts

deck sheets are more than just structural components—they define the strength, speed, aesthetics, and durability of your construction. In Delhi NCR, a trusted deck sheet dealer brings not just materials, but expertise, logistics support, and on-ground assistance. As you plan your next project, prioritize understanding your structural requirements, inspecting material samples, and choosing a reliable supplier who offers transparent pricing and technical backing.